In the transformation period of "four modernizations of automobile", intelligent networking, new energy, lightweight and intelligent manufacturing have entered the field of automobile industry, and the automobile era has been reinterpreted. The surging changes require the continuous integration and innovation of the industry to quickly promote the development rate of automobile enterprises. The emergence of autonomous driving and intelligent vehicles has given Internet enterprises, which were not active in the automotive field, more space to use; the double integral policy is becoming an important driving force for the development of China's new energy vehicle industry; in the face of environmental constraints, automobile enterprises are speeding up the implementation of advanced lightweight components and technologies to achieve vehicle weight reduction; "industry 4.0" and "made in China 2025" strategies With the continuous promotion of intelligent manufacturing, intelligent manufacturing has become a new challenge of upgrading and transformation.

Focusing on the direction of industrial development and discussing material solutions together. In order to accelerate the application of automotive lightweight and product line, under the guidance of Shanghai Economic and Information Commission and Shanghai Federation of industry and economics, the "2020 (second) China automotive new material application Summit Forum" was jointly held by Shanghai Nonferrous Metals Association, Shanghai Society of Automotive Engineering and Shanghai Nonferrous Metals Network, which was held on September 18 during the Shanghai Expo The curtain. As an excellent communication and cooperation platform for the automobile industry chain (raw materials, parts and vehicle manufacturers), many domestic and foreign colleagues in automobile material technology and market were invited to attend the meeting. During the forum, Fujian Xiangxin Co., Ltd. participated in the selection of new automotive materials and won the most potential Automotive Application Award in 2020 with 6A66 material.

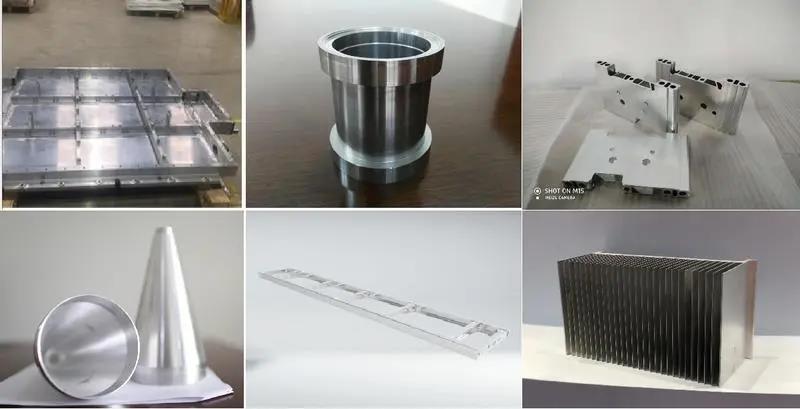

High End Manufacturing Technology Power Civil Military Integration

Fujian Xiangxin Co., Ltd. is located in Qingkou Town, Fuzhou City, Fujian Province. Founded in 2002, it covers an area of nearly 700 Mu and has more than 1000 employees. Adhering to the enterprise concept of "high-end manufacturing, science and technology power, military and civil integration", Fujian Xiangxin has always been committed to the R & D and manufacturing of ultra-high performance special aluminum alloy extrusion materials and forging materials for aerospace, weapons and ships, rail transit, automobile lightweight, national defense and military industry and other fields.

Fujian Xiangxin has strong innovation ability in science and technology. It independently develops super high strength special aluminum alloy series for aerospace, with excellent comprehensive performance and tensile strength of nearly 700MPa. Compared with traditional aluminum alloy, the strength of 6A66 and 7A21 is increased by more than 20%, and the lightweight effect is as high as 20%. In addition, it also includes ultra-high performance Al Si alloy, ultra-high corrosion resistant Al Mg alloy, ultra-high strength armored aluminum alloy and ultra-high stiffness aluminum matrix composites.

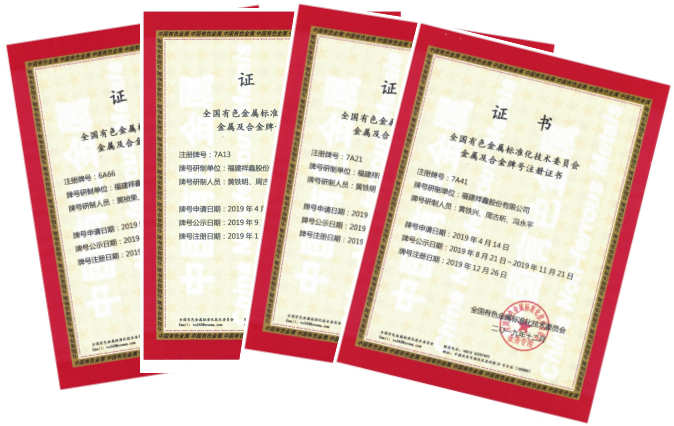

Fujian Xiangxin has a R & D team of more than 80 people, which is mainly composed of professor level and senior engineers, doctors, masters and overseas aluminum alloy experts. At the same time, it has established long-term scientific research cooperation relations with domestic and foreign universities and research institutes (Harbin Institute of technology, Fuzhou University, Central South University, Ukrainian Institute of metals and alloys, etc.), and has the domestic first-class research and development and manufacturing capacity of aluminum alloy materials and products. At present, the company has applied for 97 patents, including 40 authorized patents and 4 national aluminum alloy brands (6A66, 7A21, 7A41 and 7A13) at one time.

After 18 years of continuous innovation and development, Xiangxin has formed a "product generation, R & D generation, exploration generation" aluminum alloy material and product model. At present, Xiangxin hardware, Xiangxin special materials, Xiangxin new energy auto parts manufacturing (joint venture with BAIC Hainachuan), technology R & D center and Songshanhu materials laboratory Xiangxin joint engineering center group advantages have been formed.

Standing at the top of China's aluminum alloy manufacturing industry, Xiangxin has never forgotten its original intention. In the process of development and industrialization of new aluminum alloy materials, Xiangxin has achieved great leap forward, fully released its reserve technology, seized the strategic high point and created strategic space. The company plans to invest 3 billion yuan in the next two years to start the company's expansion project, covering an area of 400 mu, to build a new production line and supporting equipment for military civilian integration of special alloy aluminum new materials, to achieve an annual output of 500000 tons of special alloy aluminum casting rods, 250000 tons of compound alloy aluminum casting rods / alloy aluminum ingots and 300000 tons of special alloy aluminum new materials.

Post time: Apr-27-2022